Table: 6000x3000

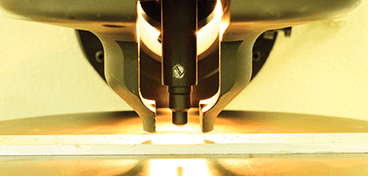

The high level of accuracy — 0.1 mm

Accuracy ± 0.05 mm loop playback

The thickness of the metal cutting 0.5-80 / 0.5-80 / 0.5-80

Rolled metal products from world leading producers

Registration and certification of the products

Quality assurance and conformity certificates

Nickel and nickel alloys are regulated by standards DIN, EN, ASME, ASTM, UNS.

Heat-Resistant Applications. Nickel-base alloys are used in many applications with high temperatures.

Corrosion Resistance. Nickel-base alloys offer excellent corrosion resistance.

Electrical Resistance. Several alloys are used in instruments and control equipment to measure and regulate electrical characteristics.

| Alloy | UNS | W.NR. | Specification ASTM / ASME | ||

|---|---|---|---|---|---|

| Nickel 200 / 201 | N022000 / N02201 | 2.4060, 2.4066 / 2.4061, 2.4068 | B/SB 160, B/SB 161, B/SB 162, B/SB 163, B/SB 366, B/SB 564, B 725, B 730, B/SB 751, B 775, B 924 |  |

|

| Monel 400 | N04400 | 2.4360, 2.4361 | B/SB 127, B/SB 163, B/SB 164, B/SB 165, B 366, B/SB 564, B 725, B 730 |  |

|

| Inconel 600 | N06600 | 2.4816 | B/SB 163, B/SB 166, B/SB 167, B/SB 168, B 366, B 516, B 517, B/SB 564, B 751, B 924 |  |

|

| Inconel 625 | N06625 | 2.4856 | ASTM/ASME B/SB 366, B/SB 443, B/SB 444, B/SB 446, B/SB 564, B/SB 704, B/SB 705, B/SB 751, B/SB 775, B 834, B 924, SB 829 |  |

|

| Incoloy 800 /

800H / 800HT |

N08800/

N08810/ N08811 |

1.4876 / 1.4958 / 1.4959 | B/SB 163, SB 240, B/SB 366, B/SB 407, B/SB 408, B/SB 409, B/SB 514, B/SB 515, B/SB 564, SB 751, B 775, B/SB 924 |  |

|

| Hastelloy C-276 | N10276 | 2.4819 | ASTM/ASME B/SB 366, B 462, B/SB 564, B/SB 574, B/SB 575, B/SB 619, B/SB 622, B/SB 626, B /SB751, B/SB 775, B 829, SB 924 |  |

|

| Expand table | |||||

| Monel R-405 | N04405 | - | ASTM B 164, ASME SB 164 |  |

|

| Monel K-500 | N05500 | 2.4375, 2.4374 | ASTM B 865, ASME BS 3072-3076 |  |

|

| Inconel 601 | N06601 | 2.4851 | ASTM/ASME B 163, B/SB 166, B/SB 167, B 168, B 366, B 924 |  |

|

| Inconel 617 | N06617 | 2.4663 | ASTM/ASME B/SB 166, B/SB 167, B/SB 168, B/SB 366, B/SB 564, B/SB 924 |  |

|

| Inconel 718 | N07718 | 2.4668 | ASTM B 637, B 670, ASME B 637, SB 670 |  |

|

| Inconel X-750 | N07750 | 2.4669 | ASTM B 637, ASME SB 637 |  |

|

| Incoloy 825 | N08825 | 2.4858 | ASTM/ASME B/SB 163, B/SB 366, B/SB 423, B 424, B/SB 425, B/SB 564, B/SB 704, B/SB 705, B/SB 751, B/SB 775, B/SB 924 |  |

|

| Hastelloy C-22 | N06022 | 2.4602 | ASTM/ASME B/SB 366, B/SB 564, B/SB 574, B/SB 575, B/SB 619, B/SB 622, B 626, B/SB 751, B/SB 775, B/SB 924 |  |

|

| Hastelloy B-2 | N10665 | 2.4617 | ASTM/ASME B/SB 333, B 335, B/SB 366, B/SB 462, B 472, B 564, B/SB 619, B/SB 622, B/SB 626 |  |

|

| Hastelloy X | N06002 | 2.4665 | ASTM/ASME B/SB 366, B/SB 435, B/SB 572, B/SB 619, B/SB 622, B/SB 626 |  |

|

| Incoloy 20 | N08020 | 2.4660 | ASTM/ASME B/SB 366, B/SB 462, B/SB 463, B/SB 464, B/SB 468, B/SB 471, B/SB 472, B/SB 473, B/SB 474, B/SB 475, B/SB 729, B/SB 751, B/SB 775, B/SB 829 |  |

|

| Problem | Solution |

|---|---|

| Do not provide a complete quality guarantee and accordance with specifications | We guarantee the quality of the supplied material. We can make by customer's request additional testing of products in independent laboratories. You can be sure that you will get products that meet international quality standards. |

| Overpayments for the small lots of goods delivery | we have several trucks on the the way with our shipments. This allows you not to overpay for small orders.

We can easily combine your order with our main deliveries or pick up from stock. |

| On the market there are no proven suppliers of not Gosstandart metal | For 6 years we have been supplying metal products according to the standards: DIN, EN, ASTM, ASME, JIS. We are working only with reliable producers and logistics companies. We have strong positions on the market and we are chosen by such companies as Gazprom, Rosatom, Lukoil, Enel and other. |

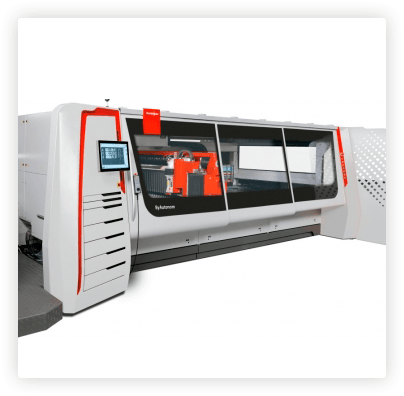

Table: 6000x3000

The high level of accuracy — 0.1 mm

Accuracy ± 0.05 mm loop playback

The thickness of the metal cutting 0.5-80 / 0.5-80 / 0.5-80

Table: 3000x1500

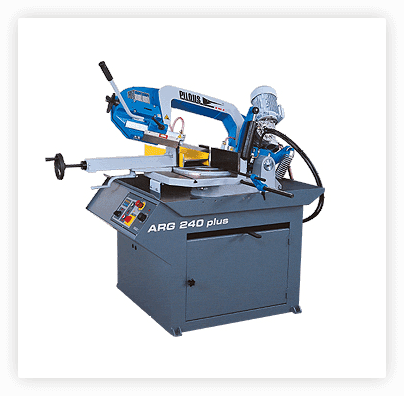

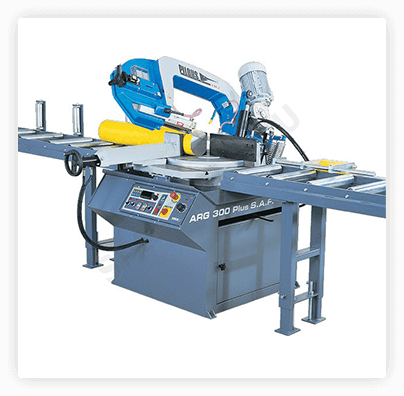

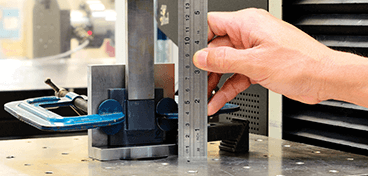

The high level of accuracy - 0.1 mm

Playback accuracy outline ± 0.05 mm

maximum cutting Ø — 240 mm;

maximum cut square — 220 mm;

maximum cut rectangular 290×180 mm.

maximum cutting Ø — 300 mm;

maximum cut square — 300 mm;

maximum cut rectangular 360x290 mm.

maximum cutting Ø — 500 mm;

maximum cut square — 500 mm;

maximum cut rectangular 750×460 mm.

Working length 3050 mm;

Max. cutting thickness 20 mm;

Cutting angle 2 degrees.

Three-roll bending machine I2222

Three-roll bending machine with DRO Metallkraft RBM 2030-60 E Pro

The four-bending machine with DRO AMS 30/16

Profile bending machine with CNC Indumasch PBT25

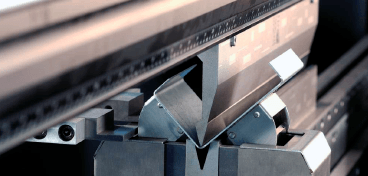

Press brakes with CNC UNICA 300-30

Press bending UA-1430

CNC bender Artech ABM 76-5

Hydraulic Press Brake with CNC XPERT 150/3100

Hydraulic straightening press P6328B

Machining center with gantry

Longitudinal mill-boring machine with CNC and DRO

Vertical milling machine with CNC and DRO

Turning and Milling with counter spindle CNC

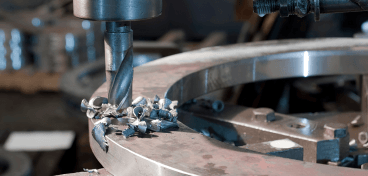

Radial drilling machine 2M-57-2

Vertical drilling machines 2S132

Radial drilling machine RD42M

Welding of aluminum alloys

Welding of stainless steel

Welding ferrous metal

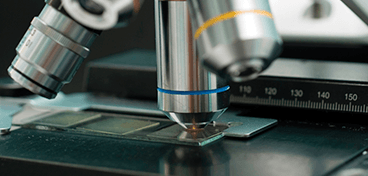

Tensile testing (ASTM / EN)

Impact toughness testing (ASTM / EN)

Hot tensile testing (ASTM / EN)

Flattening test (ASTM / EN)

Bending test (ASTM / EN)

Cooling stage testing (ASTM)

Micro- and macroscopic test

Metal interspersion testing (ASTM / EN)

Confirmation testing

Corrosion testing

Grain boundary attack testing G48, HIC, SSCC

Pitting corrosion testing

Ferrite testing

Corrosion tests according to ASTM STD / NACE

Ultrasonic test (ASTM / EN)

Magnetic examination (ASTM / EN)

Capillary test (ASTM / EN)

PMI test (ASTM / EN)

X-rays (ASTM / EN)